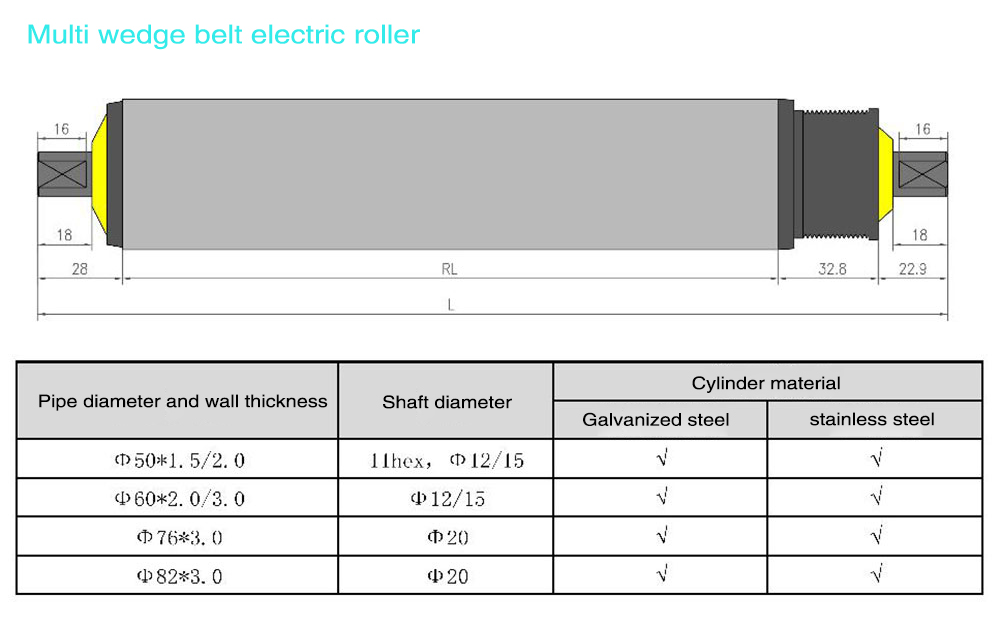

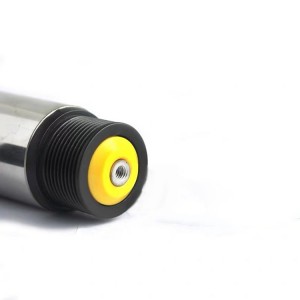

Poly-vee Conveyor Roller

1.Ts'ebetso e khutsitseng, ts'ebetso e phahameng ea lipalangoang

2.9 V-grooves, likhetho tse ling tsa PJ poly-Vee lebanta

3.Kopo ea lebelo le mahareng le le phahameng, leseli&mosebetsi o bohareng

Tšebeliso ea mochine oa drum o fetisang matla o ile oa sebelisoa pele linaheng tse ling, 'me tsoelo-pele ea oona le eona e batla e potlakile.Ka ntshetsopele le ntlafatso ya thekenoloji ya dikhomphutha, thekenoloji ya dikgokahano, thekenoloji ya taolo le thekenoloji ya ho lemoha, mmoho le tshebediso ya tsona e akaretsang, ntshetsopele ya dirolara tsa motlakase le tsona di tlisa nako e fapaneng.Ho na le mefuta e mengata ea lirolara tse tsamaisang matla, joalo ka mochini o tsamaisang lebanta la tubular, conveyor e phahameng ea lebanta, conveyor ea lebanta le joalo-joalo.Le hoja tsoelopele e saletse morao, ha ea salla morao.Patlisiso le nts'etsopele ea mahlale a macha le lihlahisoa tse ncha li fihletse litholoana tse ngata.Ka mohlala, lipatlisiso le nts'etsopele ea lebanta la telescopic, ho etsa lipatlisiso le nts'etsopele ea "angle e kholo" le "conveyor" ea mabanta a sebaka se selelele le tšebeliso ea "programmable controller" e phetha karolo e kholo ho nts'etsopele le ho tataisa nts'etsopele ea theknoloji ea ho tsamaisa lirolara.

Bakeng sa conveyor ea motlakase, tsamaiso ea tsamaiso ea motlakase ea ka tlas'a lefatše e sebelisoa haholo ho shebella ho potoloha.Sistimi ea taolo ea lirolara tsa motlakase tse ka tlas'a lefatše ke sistimi e ikemetseng e sebelisoang merafong le lipalangoang.Ha e kopantsoe le puisano ea morao-rao ea tlhahisoleseding, ha e tiise feela tsoelo-pele e bonolo ea ts'ebetso ea ka tlas'a lefatše, empa hape e eketsa katleho ea tlhahiso le ho hlokomela melemo e metle ea tsamaiso ea moruo.Ka nako e ts'oanang, ts'ebeliso ea taolo ea othomathike ea mochini e boetse e tiisa ka katleho kaho, e fokotsa matla a tlhahiso le taolo ka hohle kamoo ho ka khonehang, 'me e na le ts'epo e ntle.