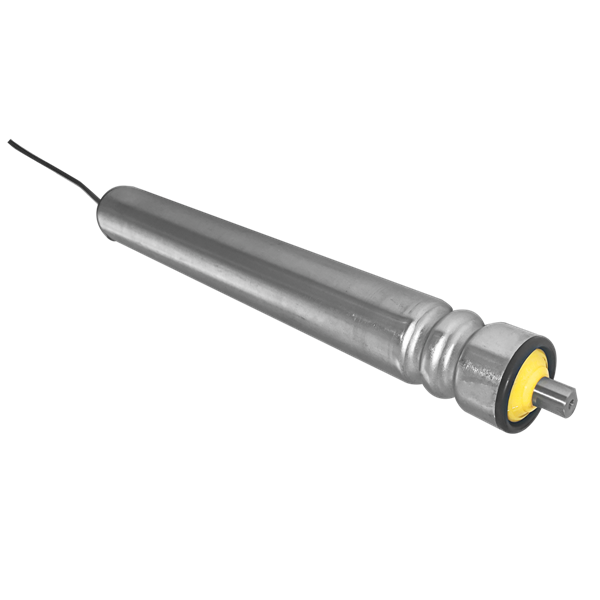

Double Grooved O-belt Conveyor

1.Simple sebopeho, groove boemo customized

2.Ts'ebetso e khutsitseng, moralo o tloaelehileng oa anti-static

3.Kopo ea mosebetsi o bobebe & o bohareng

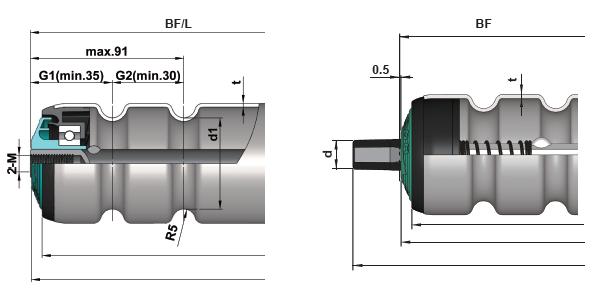

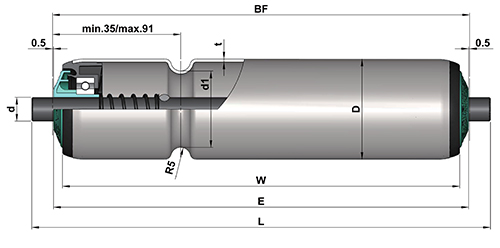

| D | T | Shaft | Tube | |

| Tšepe Z/P | SS | |||

| Φ48.6 | 1.5 | 11hex,Φ10/12/14/15 | √ | √ |

| Φ50 | 1.5 | 11hex,Φ8/10/12/14/15 | √ | √ |

| Φ60 | 2.0 | 11hex,Φ10/12/14/15 | √ | √

|

Tlhokomeliso: Lirolara tsa Φ50 li ka kenngoa letsoho la PU (2mm).

Φ50, lirolara tse 60 li ka kenngoa letsoho la PVC (2mm).

11hex e ka fana ka rolara e entsoeng ka tšepe e entsoeng ka tšepe e entsoeng ka tšepe.

Tsamaiso e tsamaisoang e tsamaisa thepa ka mokhoa o tsitsitseng, ka botšepehi le ka lebelo le nepahetseng.Ho latela mokhoa oa ho khanna, e ka hlalosoa e le "ho tsamaisa lebanta" kapa "ho tsamaisa ka chian".

E tsamaisoang ka lebanta:

Lerata le tšepahalang, le tlase, tšilafalo e tlase ea tikoloho, e khona ho matha ka lebelo le phahameng.Maemo a sebetsang a mafura a lokela ho qojoa.

E tsamaisoa ke ketane:

Boima bo phahameng ba mojaro.E loketse mefuta e mengata ea libaka tse sebetsang ho kenyeletsa oli, metsi le mocheso o phahameng leha ho le joalo ketane e apara habonolo sebakeng se lerōle.Lebelo la ho tsamaisa ha lea lokela ho feta 30m / min.

Rolara ea motlakase ke moloko o latelang oa sistimi e tsamaisang lirolara tsa motlakase.Litsamaiso tse akaretsang tsa conveyor li sebelisa lienjene tse kholo tse sebetsang hantle tse sebetsang khafetsa le ho fana ka matla ho ba tsamaisang nako e telele.Tsamaisa lihlahisoa ho ea libakeng tse nyane.

"Sistimi ea rona e fa bareki ba rona mesebetsi e hlokahalang le katleho 'me e fokotsa nako ea tlhokomelo. Sebopeho sa sensor ea actuator ke tharollo ea marang-rang e bulehileng ea indasteri e fokotsang ho rarahana ha li-wiring le ho eketsa mesebetsi ea taolo, e leng tharollo e loketseng bakeng sa mekhoa e joalo ea li-roller conveyor. mekhoa ea ho sebetsana le thepa e sebelisang mabanta a tsoelang pele ho tsamaisa lihlahisoa kapa thepa.

Lebanta le fetela pakeng tsa li-pulleys tse peli tse qetellang.Hangata, ntlha e le 'ngoe kapa ka bobeli e kenyelletsa moqolo o ka tlase.Lebanta la conveyor le tšehelitsoe ka thata ke li-discs tse thellang tsa tšepe ho jara mojaro o bobebe ntle le khohlano holim'a lebanta la conveyor ho tsosa khanyetso kapa khohlano ho lirolara.Matla a fanoa ke enjene ea motlakase e sebelisang lebelo le feto-fetohang kapa likere tse sa khaotseng tsa ho fokotsa.

Lebanta ka boeona le ka etsoa ka lisebelisoa tse sa tšoaneng 'me le lokela ho finyella maemo a sebetsang a lebanta.Lintho tse tloaelehileng tsa lebanta la conveyor li kenyelletsa rabara, polasetiki, letlalo, lesela le tšepe.Ho tsamaisa lintho tse boima ho bolela hore ho hlokahala thepa e teteaneng le e matla ea lebanta la conveyor.Hangata li-conveyor tsa mabanta li tsamaisoa ka matla 'me li ka matha ka lebelo le fapaneng ho ea ka sephetho se lebelletsoeng.Conveyor e ka sebetsoa ka mokhoa o tšekaletseng kapa oa sekamisoa.